A bioreactor is a vessel in which chemical processes occur. These processes can be anaerobic or aerobic. Anaerobic process occurs when and organism does not need oxygen for growth or productions. In fact, the microorganism can react negatively to oxygen, or even die. An aerobic organism is one that can survive and grow in an oxygenated environment. Depending on the industry a bioreactor will serve, the application will determine if the process is an anaerobic or aerobic.

While each bio reaction process is different the operational stages of a bioreactor can be similar. A bio process is composed of three stages. These are upstream processing, bio reactions, a downstream processing. Before any processing steps raw material is converted and broken down so bio reaction processes can occur quicker. This can be done by an upstream process. This involves chemical hydrolysis, preparations of liquid medium, separation of particulate, air purification, and other preparatory steps. By using some or all of these steps the materials will be easier to create a reaction within the bioreactor.

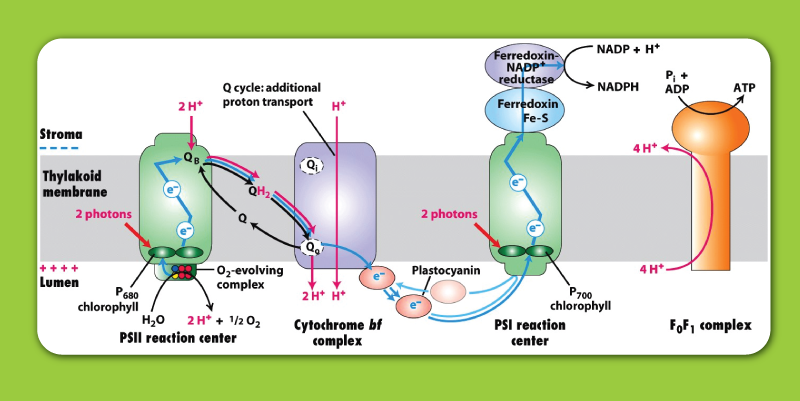

The next step is the bio reaction stage. This is where the bioreactor holds all the parts for a chemical reaction to occur. During this reaction different sub steps can occur. These are called production of biomass, metabolize biosynthesis and bio transformation. Biomass is organic matter that can be used as a source of energy. Biomass production is usually plant based, but is not used for food or feed. Biomass can be used via combustion to produce head or can be used in various forms of bio fuel. Biosynthesis is a multi-step process. It involves an enzyme-catalyzes relationship. In this relations an enzyme is accelerated to increase the rate of a chemical reaction. The process has the broken down material turn into more complex products. Bio transformation is the modification of an organism on a chemical compound. Bio transformation, just the bio chemical reactions, can vary from application.

The third operation process is the material that is produced must be further processed. This allows the new product to be converted into a more useful form. This can be the separation of solids from liquids, liquid -liquid extraction, and even distillation. These operational steps are common in all bioreactor process but will allow for variety depending of the production.

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

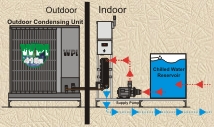

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |